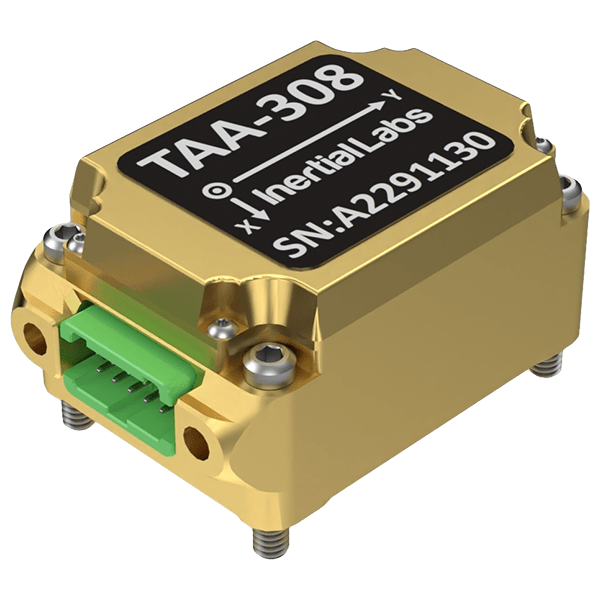

Three Axis Accelerometers (TAA)

Three Axis Accelerometers

The Inertial Labs MEMS TAA-308, TAA-315 and TAA-340 are the third generation of the Inertial Labs MEMS, three-axis high-precision accelerometers released in a stand-alone design. The TAA-308, TAA-315 and TAA-340 are revolutionary, compact, self-contained, strapdown, Navigation-grade Accelerometers that measure linear accelerations with high precision due to their unique design and developed by Inertial Labs over last 20 years several significant know-know and technics in calibrations of inertial sensors. Measured by TAA Accelerometers accelerations are determined with low noise and very good repeatability for both motionless and dynamic applications.

TAA Models

| MODEL |

|

|

|

|

|

|

| TAA-308 | TAA-315 | TAA-340 | TAA-308EC | TAA-315EC | TAA-340EC | |

| Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | |

| Measurement range | ±8g | ±15g | ±40g | ±8g | ±15g | ±40g |

| Interface | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs |

| Bias in-run stability | 0.005 mg | 0.01 mg | 0.02 mg | 0.003 mg | 0.005 mg | 0.01 mg |

| Bias residual error (in temp. range, RMS) | 0.5 mg | 0.7 mg | 1.2 mg | 0.2 mg | 0.3 mg | 0.5 mg |

| Bias one-year repeatability | 1.0 mg | 1.3 mg | 1.5 mg | 0.35 mg | 0.45 mg | 0.55 mg |

| SF accuracy (over temp. range) | 150 ppm | 300 ppm | 500 ppm | 50 ppm | 100 ppm | 200 ppm |

| SF one-year repeatability | 500 ppm | 1300 ppm | 1500 ppm | 200 ppm | 400 ppm | 550 ppm |

| Noise (VRW) | 0.015 m/sec/√hr | 0.035 m/sec/√hr | 0.045 m/sec/√hr | 0.01 m/sec/√hr | 0.02 m/sec/√hr | 0.03 m/sec/√hr |

| Size (mm) | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 |

| Weight (gram) | 13 | 13 | 13 | 13 | 13 | 13 |

| Model | TAA-308 | TAA-315 | TAA-340 | TAA-308EC | TAA-315EC | TAA-340EC |

| Datasheet, PDF |

| MODEL |

|

|

|

|

|

|

| TAA-308 | TAA-315 | TAA-340 | TAA-308EC | TAA-315EC | TAA-340EC | |

| Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | Three Axis Accelerometer | |

| Measurement range | ±8g | ±15g | ±40g | ±8g | ±15g | ±40g |

| Interface | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs | RS-422 + discrete IOs |

| Bias in-run stability | 0.005 mg | 0.01 mg | 0.02 mg | 0.003 mg | 0.005 mg | 0.01 mg |

| Bias residual error (in temp. range, RMS) | 0.5 mg | 0.7 mg | 1.2 mg | 0.2 mg | 0.3 mg | 0.5 mg |

| Bias one-year repeatability | 1.0 mg | 1.3 mg | 1.5 mg | 0.35 mg | 0.45 mg | 0.55 mg |

| SF accuracy (over temp. range) | 150 ppm | 300 ppm | 500 ppm | 50 ppm | 100 ppm | 200 ppm |

| SF one-year repeatability | 500 ppm | 1300 ppm | 1500 ppm | 200 ppm | 400 ppm | 550 ppm |

| Noise (VRW) | 0.015 m/sec/√hr | 0.035 m/sec/√hr | 0.045 m/sec/√hr | 0.01 m/sec/√hr | 0.02 m/sec/√hr | 0.03 m/sec/√hr |

| Size (mm) | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 | 28.5 x 19.5 x 13.6 |

| Weight (gram) | 13 | 13 | 13 | 13 | 13 | 13 |

| Model | TAA-308 | TAA-315 | TAA-340 | TAA-308EC | TAA-315EC | TAA-340EC |

| Datasheet, PDF |

Use Cases for the TAA

Aerial Vehicles

Accelerometers are crucial in ensuring flight stability in drones and other aerial vehicles. These sensors detect any changes in acceleration, which are essential for understanding the vehicle’s movement in three-dimensional space. When a drone is in flight, it experiences various forces and motions, such as lifting, descending, tilting, or accelerating forward. The accelerometer continuously monitors these changes in acceleration. This data is then fed into the flight control system. With this information, the control system makes real-time adjustments to the drone’s rotors and propulsion system to maintain balance and stability. This process is vital, especially in turbulent conditions or when performing complex maneuvers, ensuring the drone remains steady and responsive to control inputs. Thus, accelerometers are fundamental components that contribute significantly to the agility and stability of aerial vehicles.Industrial automation and control systems

Accelerometers are sophisticated devices integral to the predictive maintenance of machinery. These instruments detect vibrations and movements within mechanical systems, which are vital indicators of the machine’s operating condition. By continuously monitoring these vibrations, accelerometers provide valuable data on the performance and health of the machinery, allowing for early identification of irregularities or potential malfunctions. With this information, maintenance can be proactively scheduled to address issues before they escalate into significant problems or failures. This proactive approach enhances the machinery’s longevity and reliability and optimizes operational efficiency and safety. In essence, accelerometers act as an early warning system, enabling timely interventions that prevent costly downtime and extend the life of the equipment.

Vibration monitoring and analysis

Accelerometers play a crucial role in maintaining the safety and integrity of various structures and machines. They are sophisticated devices specifically designed to monitor and analyze vibrations. These accelerometers can detect even the slightest irregular movements or oscillations when installed in systems like buildings, bridges, or machinery. By analyzing these vibrations, accelerometers help identify potential problems or weaknesses in the structure or machinery. This early detection is vital as it allows for timely interventions, preventing possible malfunctions or structural failures. Thus, accelerometers are essential in ensuring the safety and longevity of critical infrastructures and mechanical systems.TAA Supported Software

Inertial Labs supplies drivers and tools for easy integration with commonly used platforms such as ROS, LabVIEW, and Waypoint products. Additionally, take advantage of the Software Development Kit to create custom solutions for your application.

SDK

A Software Development Kit (SDK) allows developers to customize the processing workflow to suit their customers or application.

Post-processing is ideal for applications requiring highly accurate post-mission position, velocity, or attitude.

LabVIEW

ROS

ROS (Robot Operating System) is an open-source software development kit for robotics applications. ROS offers a standard software platform to developers across industries that will carry them from research and prototyping to deployment and production.

Performance Characteristics for the TAA

TAA Low-g Accelerometer Allan Deviation Test

TAA High-g Accelerometer Allan Deviation Test

Development Kits and Unboxing

Trademark Legal Notice: All product names, logos, and brands are the property of their respective owners. All company, product, and service names used in this document are for identification purposes only. Use of these names, logos, and brands does not imply endorsement. ABS, BeiDou, Cobham Limited, EdgeTech, Galileo, GLONASS, GPS, Hexagon, HYPACK, IMAGENEX, Kongsberg Seatex, LabVIEW, Livox, Norbit, NovAtel, NovAtel Inertial Explorer, Ouster, Qinsy, Quanergy, QZSS, R2Sonic, RIEGL, ROCK Robotic, ROS, Septentrio, Ship Motion Control SMC, Teledyne TSS, u-blox, Velodyne, WAASP, Waypoint.